What have we done?

Project Portfolio

This is a selection of projects, products and other interesting activities I've been a significant part of developing. This is supposed to be a selection highlighting significant and diverse projects in different areas, not an extensive list of everything.

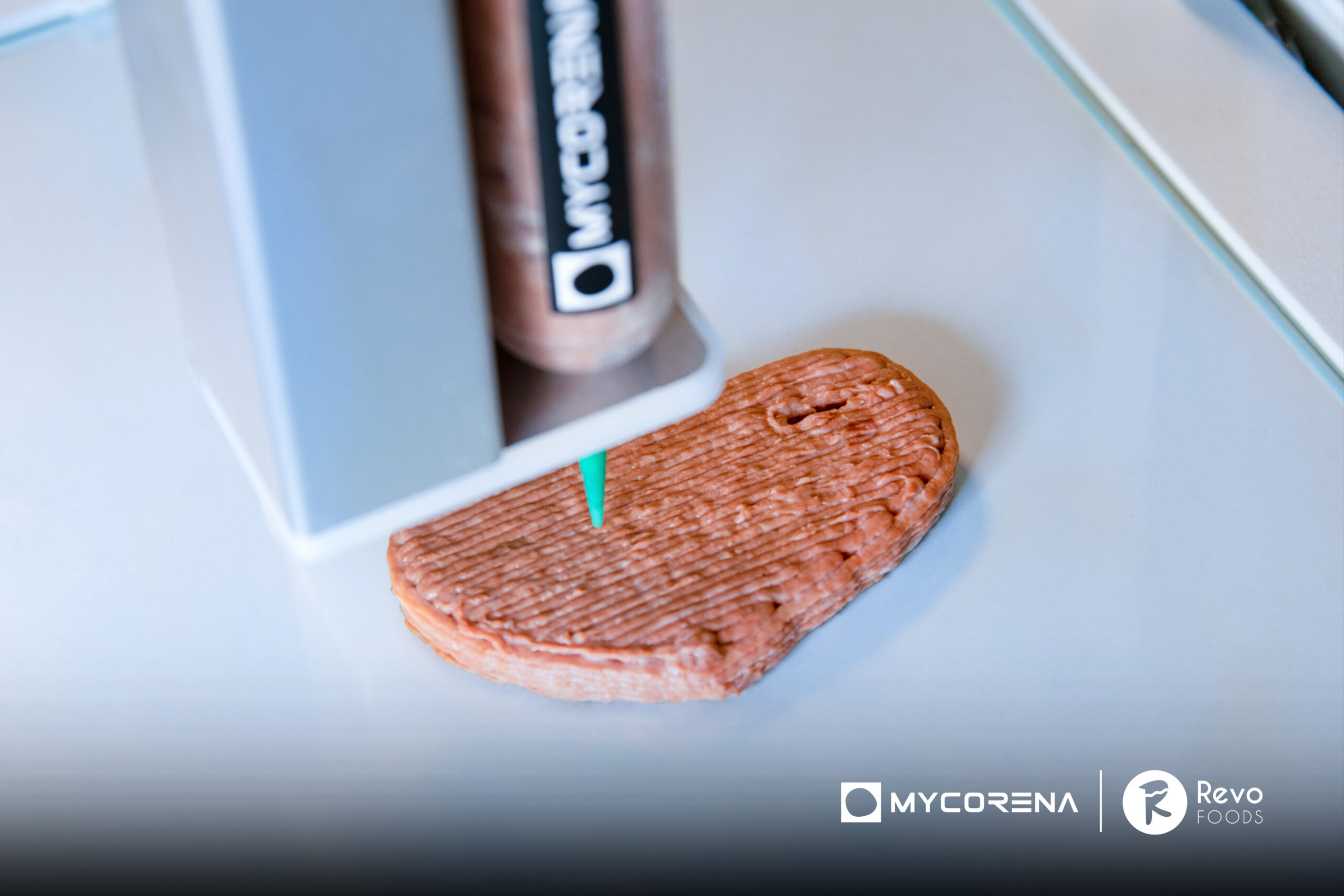

Mycorena AB

Promyc: a B2B mycoprotein ingredient

Image property of Mycorena, part of Naplasol

Promyc is a mycoprotein ingredient developed by Mycorena AB (today aquired by Naplasol). Promyc is a protein- and fiber-rich mycelium to be used by food manufacturers in the development of food products, delivering major advantages over other plant-based proteins, such as enhanced textures and lack of off-tastes.

Promyc was first launched in 2018, and the first product was developed by our initial technical team at Mycorena (Paulo Teixeira, Silvia Huttner and Frida Persson). From there, Mycorena scaled the product to Pilot scale in 2021, and initiated building of its commercial production facility in 2022. Troughout this time, we have validated in end products through product launches in ICA supermarkets in Sweden, by Rebl Eats in Finland and by Revo Foods in Austria.

Mycorena AB

Mycoprotein: Process, IP and Licensing

Image property of Mycorena, part of Naplasol

During 5 years of product development and innovation at Mycorena, our technical team has created numerous inventions related to mycelium and mycoprotein production, resulting in a series of proprietary processes and 12 patent families filed.

We then explored commercialization of these products, processes and tecxhnologies through exploration of licensing agreements, joint-venture collaborations and provision of R&D services to companies in the field.

NASA | European Space Agency

Space food production through a Fungi-Algae system

Image property of Mycorena, part of Naplasol

This project was developed by an innovation sub-team at Mycorena, composed of Carlos Núñez Otero, Kristina Karlsson and Paulo Teixeira. We designed a system that would allow astronauts to grow their own nutritious and tasty food in space using a compact system. The system used sunlight to create algae, and the use these algae as nutrients for growing nutrition fungal mycelium, and 3D print it into delicious food.

The project was elected a winner of the NASA Deep Space Food Challenge and received a European Space Agency (ESA) grant for continued development.

Mycorena AB

Innovative Mycelium Products

Image property of Mycorena, part of Naplasol

Throughout development of mycelium ingredients and products for food industry applications, our development team at Mycorena created a variety of applications that delivered novelty and unique advantages. Some of these products and innovations included:

> Mycelium ingredients produced from cicrular waste streams from the food industry, developing extremely low-carbon production systems

> A structured fat ingredient (Mycolein) using mycelium as a functional ingredient

> Mycelium ingredients adapted for 3D printing technologies (used by Revo Foods)

> Dairy-replacement applications and methods

> Technology for aligning mycelium fibers through modified cold-extrusion processes

> Nutritiously enhanced mycelium by using algae as part of the feeding system

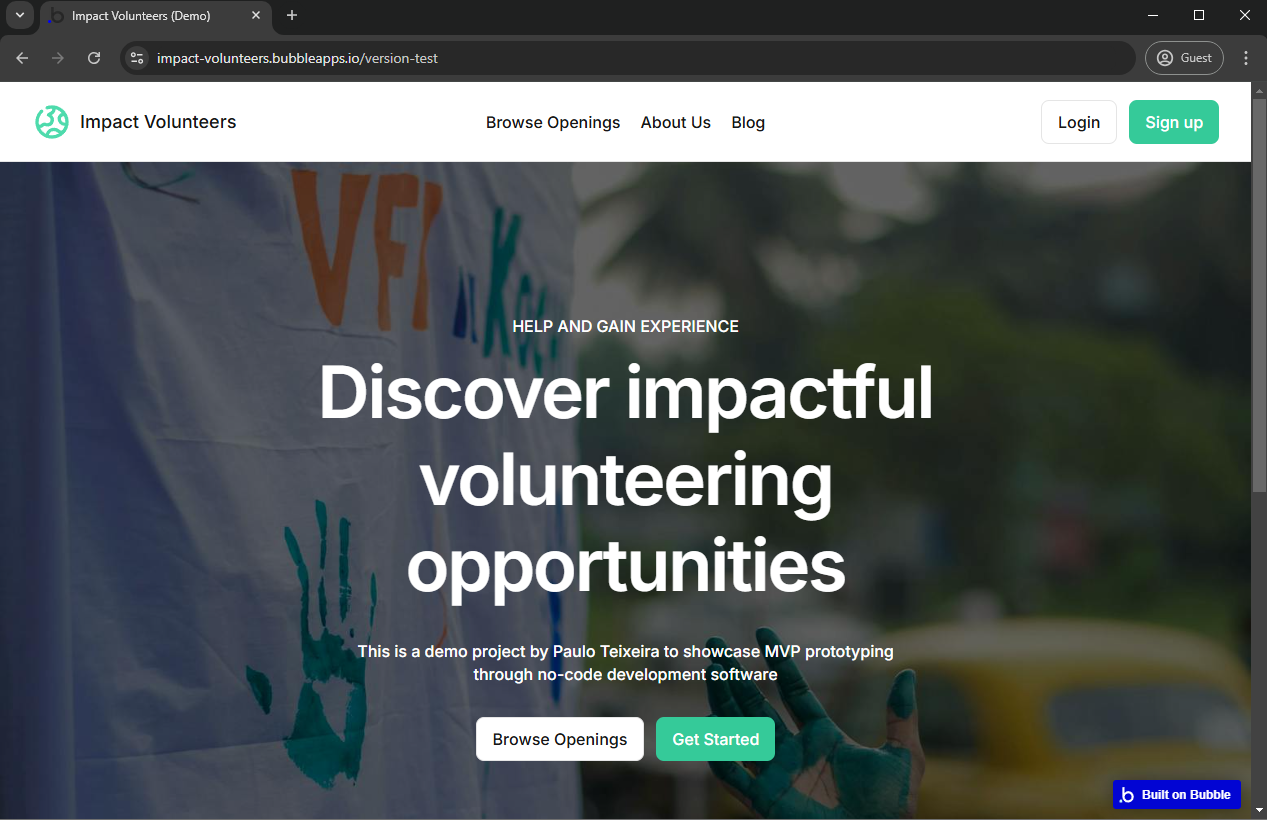

Independent work

Web apps: prototyping and MVP development

As part of MVP design, idea testing and product-market fit work, I've indendeptly developed web apps using no-code tools. This method allows fast development (a few days/weeks) of stylish prototypes with full functionalities including databases, user accounts, responsive design etc. This can easily be used as a full product for early-stage development and market assessment and are a crucial part of launching any new product or business.

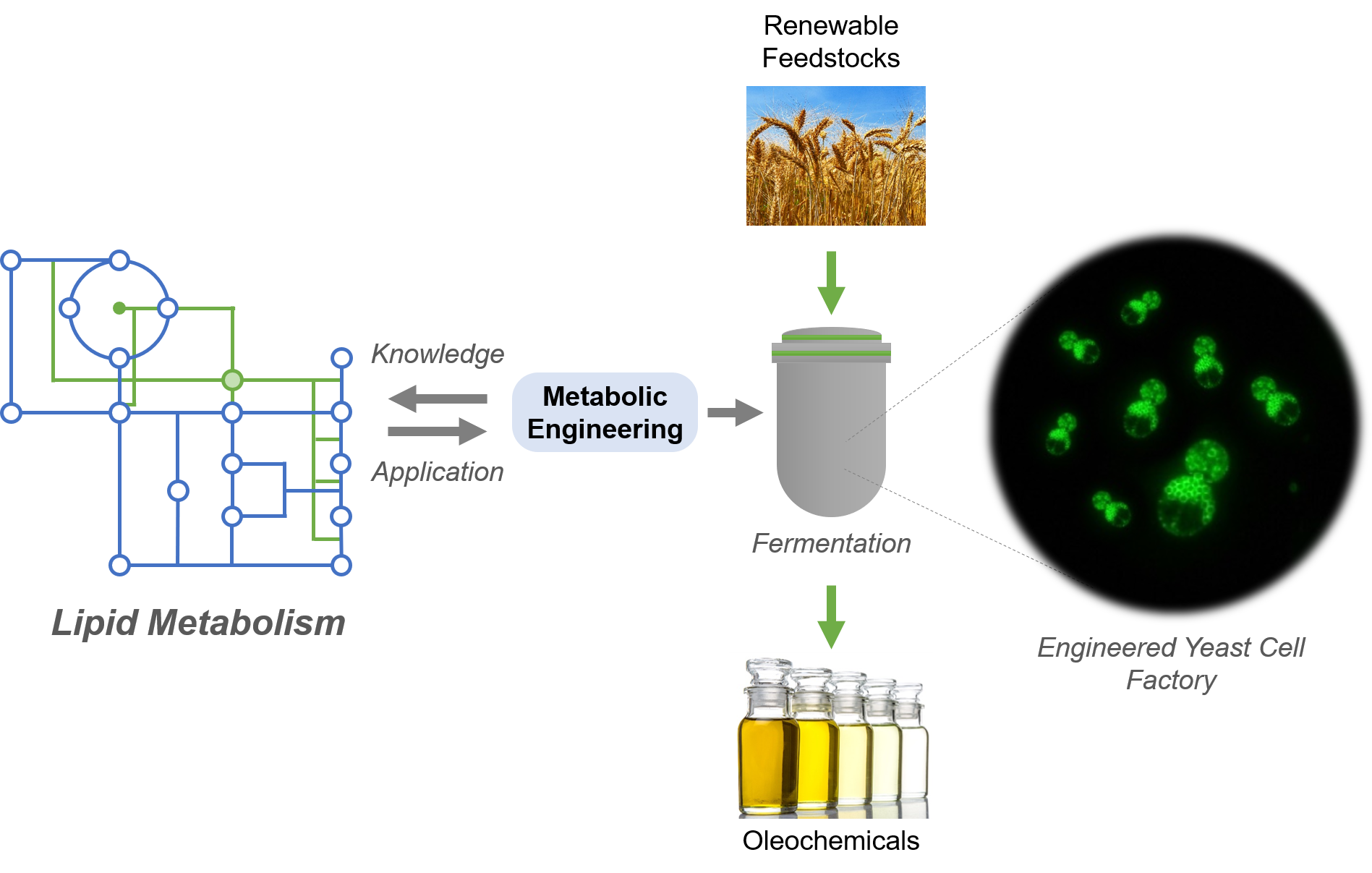

Chalmers University of Technology | Melt & Marble AB

Fats & Oils Production through Engineered Yeasts

This project was my PhD Thesis and Post-doc work in Jens Nielsen's lab at Chalmers University of Technology.

Here, I developed a number of yeast cells to be used for production of sustainable fats, oils, lubricants and biofuels through precision-fermentation processes. The work resulted in 8 peer-review papers, 2 patent applications and the technology is today used for efficient production of fats for the food industry.

Through these projects, we worked with companies such as Total Energy, AAK and Novogy (today part of Ginkgo Bioworks).

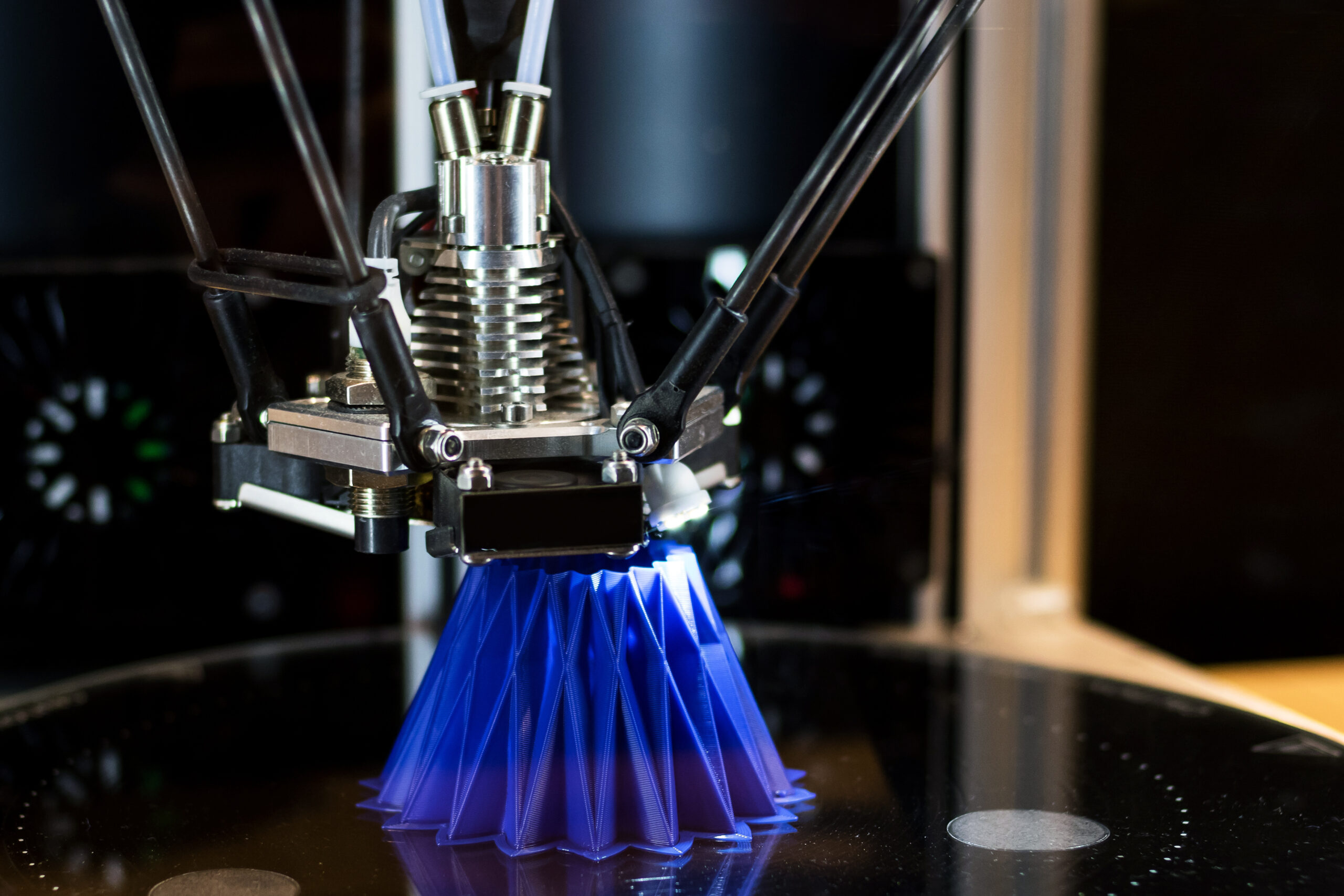

j3Diworks (self-owned business)

3D printing & e-commerce

During my research years, I've also run an online business for 3D printed parts. Initially a hobby project, the business focused on providing custom CAD design and 3D prints for end-customers, as well as the production of different custom design pieces for hobbies. I have through this set up a printing room with different machines operating in parallel, and sold the produced parts through online marketplaces, as well as in hobby events.

With so many possibilities of what can be done

The question is: What's next?

There's a lot more than the above, but this should be anough to tell you that creating impact is possible no matter how we want to do it.